Launching a New Era in Copper Production

JinChuan Group Co., Ltd. has taken a bold leap forward in copper production with the full activation of the intelligent storage and transportation system for its 400,000-ton/year intelligent copper electrolysis project. Located in the Hexipu Industrial Park of JinChang Economic and Technological Development Zone, this initiative stands as a flagship provincial construction project and a cornerstone of the 14th Five-Year Plan (2021-25). By integrating cutting-edge technology,JinChuan is redefining efficiency and sustainability in the copper industry.

Advanced Electrolysis Boosts Efficiency

At the heart of the project is an advanced stainless steel permanent cathode electrolysis process, designed for low energy consumption and high electrical efficiency. Built on an industrial Ethernet backbone, the system ensures seamless intelligent communication across electrolytic cranes, units, and transportation networks. This enables smart handling of anode plates and cathode copper products, real-time online detection of electrolytic cells, and unmanned operation of loading and unloading equipment. The result is a streamlined, high-efficiency production line that minimizes human intervention while maximizing output.

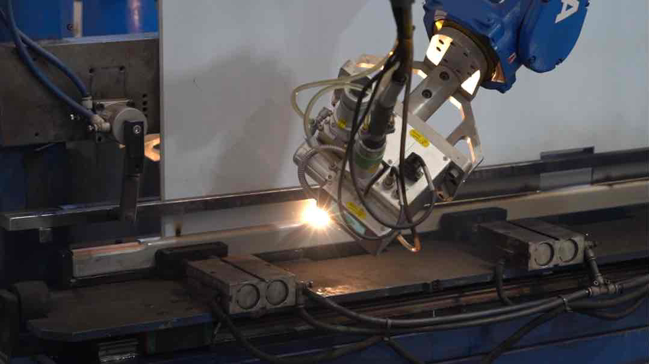

Smart Storage Transforms Operations

A standout feature is the intelligent storage and transportation system for copper anode plates, a critical component of the project’s smart infrastructure. This system harnesses technologies like low-voltage rail power supply, servo control, industrial IoT, RFID, and intelligent data analysis. From the disc casting system to the electrolysis units, it automates the handling, shaping, storage, retrieval, and transportation of anode plates—achieving fully unmanned operations. This breakthrough has dramatically boosted efficiency, reduced onsite risks, and created a cleaner, safer working environment.

A Leap Toward Intelligent Manufacturing

Technical experts on the project hail this development as a game-changer, describing it as a "smart wing" that elevates JinChuan’s copper industry into the realm of intelligent manufacturing and digital factories. The system’s launch marks a pivotal step in the company’s journey toward high-quality development, aligning with President Xi Jinping’svision of innovation-driven progress. By producing 400,000 tons of copper annually with reduced energy use and enhanced precision,JinChuan is setting a new standard for the global copper sector.

Data-Driven Future Enhances Sustainability

Looking ahead, the project team is focused on refining its data-driven approach. Using big data analysis, they aim to respond swiftly to shifts in electrolysis demands, optimizing production and logistics in real time. This commitment to continuous improvement ensures the project will evolve toward greater efficiency, greener practices, and smarter operations—solidifying JinChuan’s leadership in copper electrolysis and its role as a pioneer in sustainable industrial innovation.

Building a World-Class Sustainable Legacy

As JinChuan Group continues to advance its technological capabilities, the 400,000-ton/year intelligent copper electrolysis project stands as a testament to its ambition: to build a world-class enterprise that balances economic success with environmental responsibility.