1、Standard

The product is manufactured according to the standard of GB/T 1179-2008 or GB/T 1179-1983, and the same time is also manufactured according to the standard of IEC 61089-1991.

2、Application

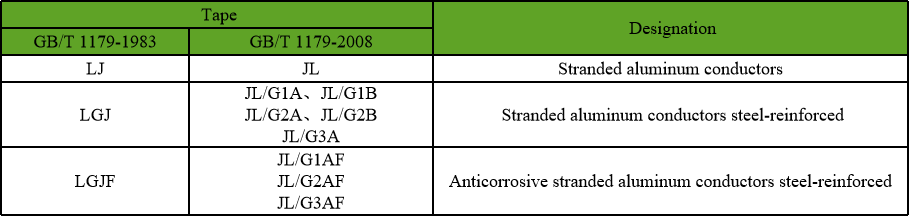

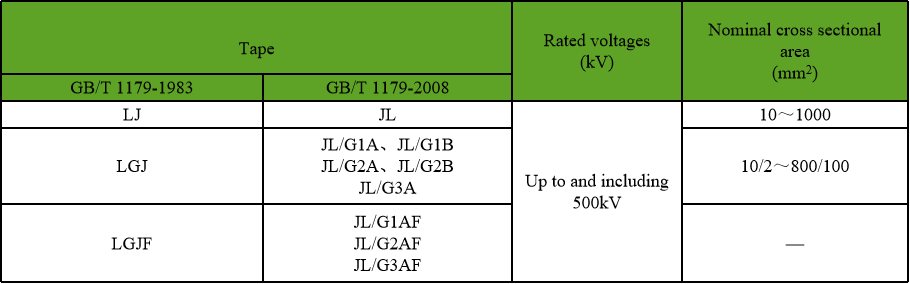

The Aluminum Stranded Wire and Aluminum Conductors Steel-Reinforced apply for electric transmission line overhead.

3、 Specification

4、Produce range

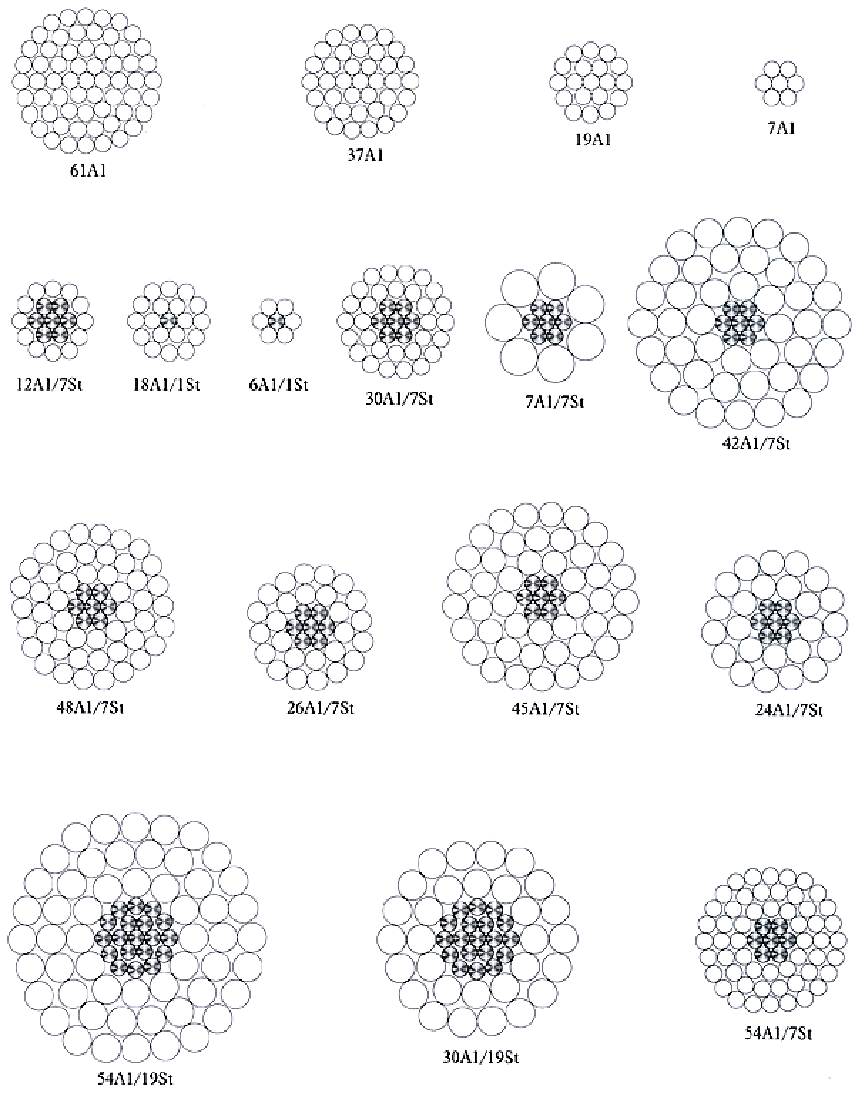

5、Structure charts of Aluminum Stranded Conductors and Aluminum Conductors Steel-Reinforced

6、Construction And Technical Data

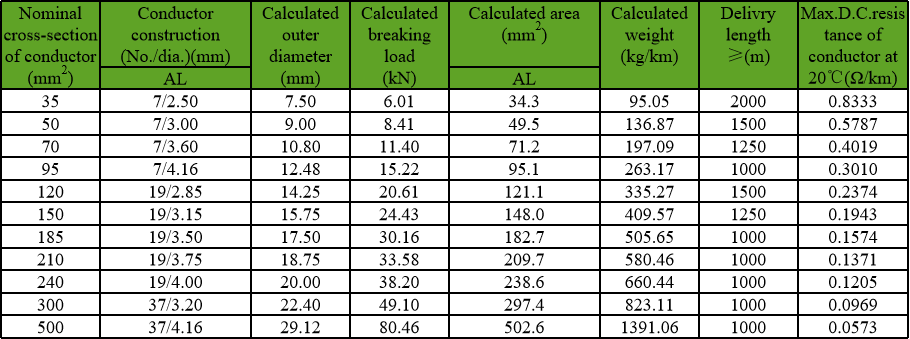

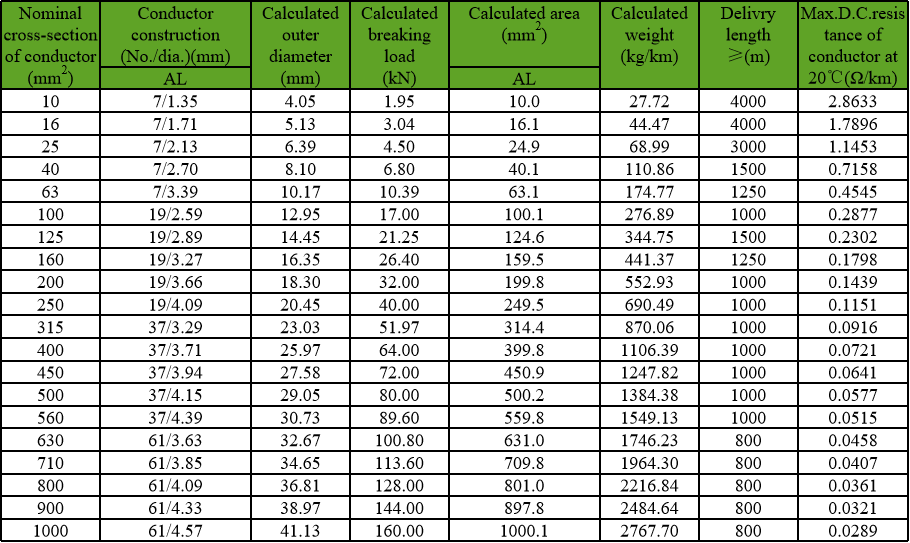

1. Aluminum stranded conductors

1) Commonly used aluminum stranded conductors in the country(JL)

2) IEC 61089 Aluminum stranded wire(JL)

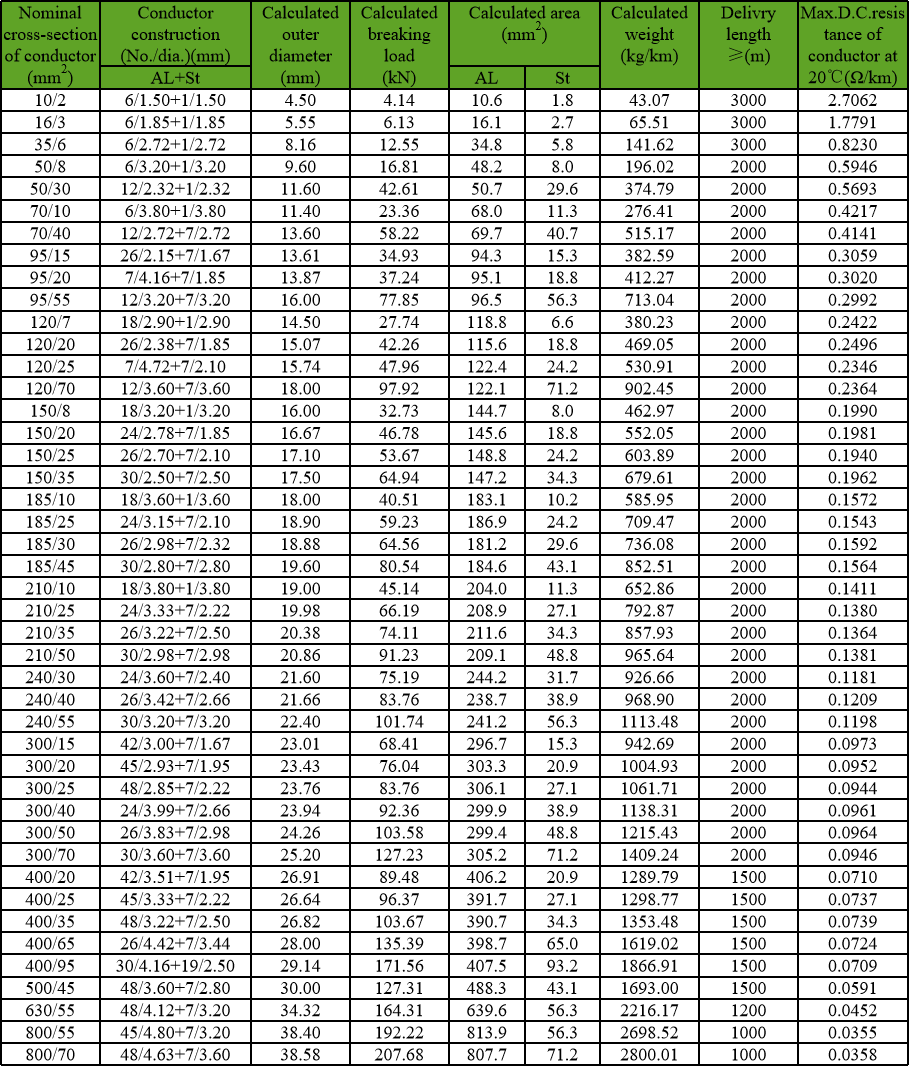

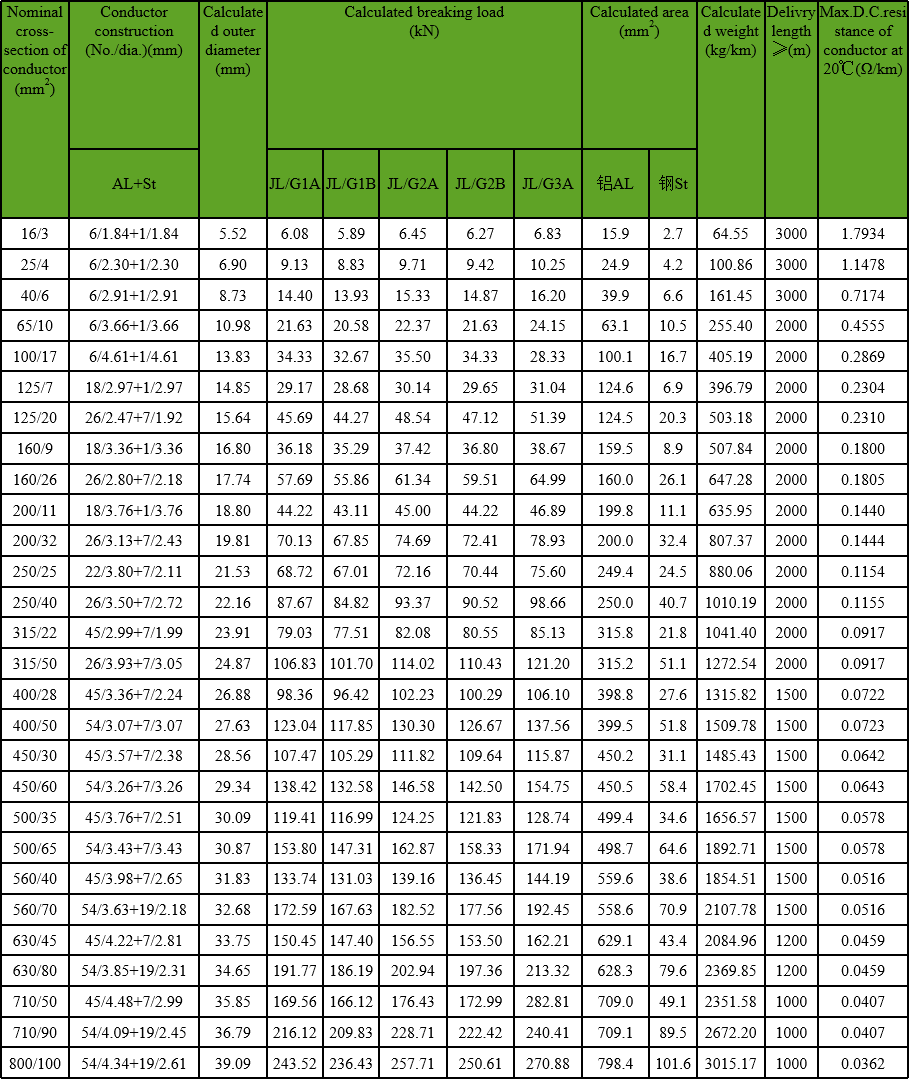

2. Aluminum conductors steel-reinforced

1) Commonly used aluminum conductors steel-reinforced in the country(JL/G1A)

2) IEC 61089 Aluminum conductors steel-reinforced(JL/G1A、JL/G1B、JL/G2A、JL/G2B、JL/G3A)

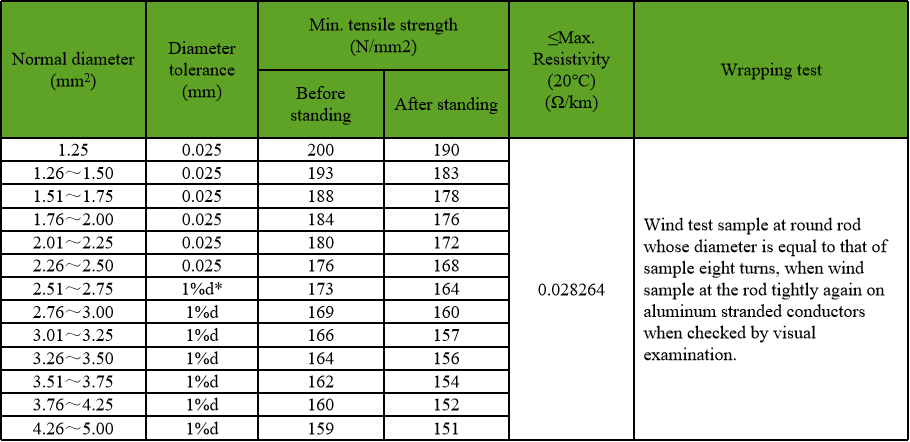

3)Aluminum wire conductor

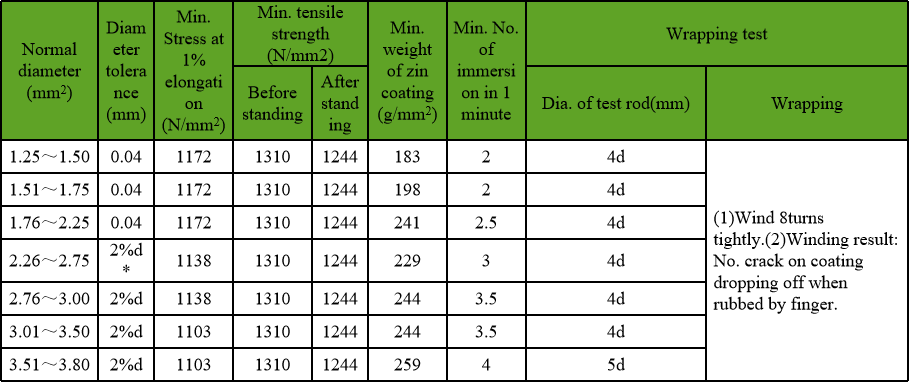

4) Galvanized steel wire

Note:d express steel wire diameter.

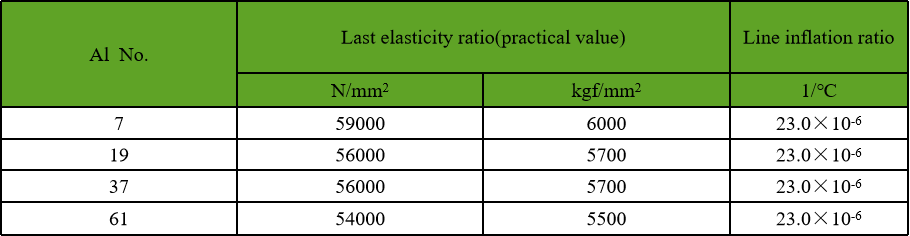

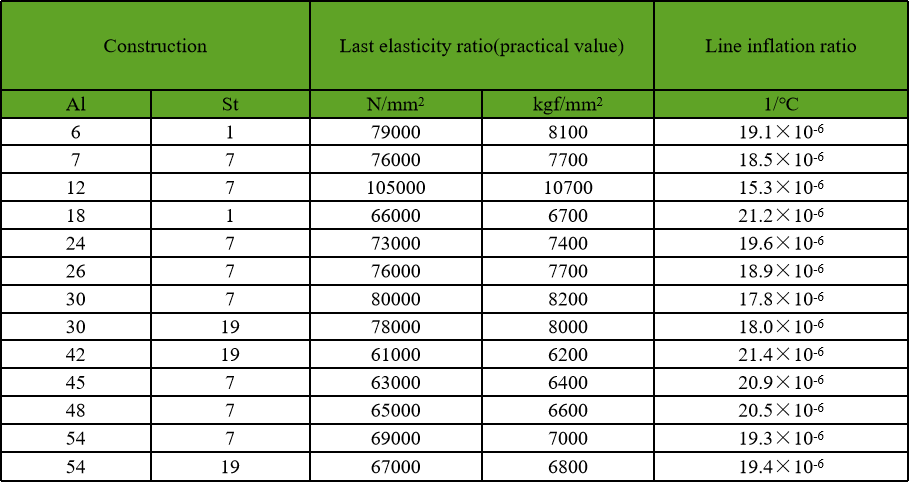

7、Aluminum stranded conductor and aluminum conductor steel-reinforced last elasticity ratio and line inflation ratio

1)Aluminum stranded conductor

2)Aluminum conductor steel-reinforced

8、Type test item of characteristic test adapt aluminum conductor steel-reinforced used in 500 kV line

1)Wriggle variation performance parameter

Sample number :4(for example LGJ-720/50)

Test condition sample length:

Length of two end sample:14m

Treatment of two end sample: epoxy resin pouring

Testing valid length of the simultaneity elongation instrument

Rest temperature:20 ±1℃

Test precision:

Stress: ±1%

Strain: ±0.01mm/5000m

Sample tension:25.59kN(15%RTS)

42.66kN(25%RTS)

59.71kN(35%RTS)

sample record time: when tension loading reach a value, homologous value of elongation and temperature are recorded at the increasing time of 1、2、3、4、5、6、7、10、15、30、60 minutes;following three day, the value are recorded every one hour; form day to the five day, the value are record every two hour; form the six fourteen day, the value are recorded every four hour; from the fifteen day, the value are recorded every six hour, the testing time is 1000 hour.

Test result: The wriggle variation equation at the 15%RTS、25%RTS、35%RTS、tension loading can deduce the wriggle variation value as following: 280、541and 794mm/km.

2)Vibratory fatigue test

Vibratory parameter: Vibratory angle: 25~300, tension is the percent 25 of breaking;

Vibratory time: 3 × 107

Test result: single aluminum wire non-breaking.