For XLPE insulated power cable, either chemical method or physical method is method is employed to transform the molecular structure of PE from chain into three-dimensional network, i. e. thermo-plastic PE is transformed into thermosetting XLPE. After cross-linking, the thermal and mechanical properties of PE have been greatly improved while its excellent electrical property are still retained.

The maximum permissible operating temperature of the conductor of a XLPE insulated power cable is 90℃ which is higher than that of paper, PVC or PE insulated power cable. The cable has the advantage of simplicity in construction, lightness in weight, convenience in application besides its excellent electrical, thermal, mechanical and anti-chemical corrosion properties. It can also be laid with no limitation of level difference along the route.

1、Standard

The product is manufactured according to the standard of 《GB/T 12706 or IEC、BS、DIN and ASTM 》.

2、Applications

This product is applicable to being fixedly laid on the transmission and distribution line of alternative current rating 50Hz and rated voltage up to 3.6/6kV~26/35kV with the use for power transmission, which is applied to the range of distribution network, industrial equipments, etc.

This product is normal used cable, not suitable for some special situation, such as aerial, underwater, ship, sea, nuclear station, etc.

XLPE insulated flame-resistant cable is suitable for the cable with flame retardant properties.

XLPE insulated fire-resistant cable is suitable for the requirements of buildings, fields, power plants, power plants, mining, chemical industry, mine, subway fire conditions are occasions - also emergency power, fire pumps, elevators communication signal system cables should be prepared the product has a higher degree of fire-resistant, withstand direct flame burning in a certain period of time (not less than 3h) short circuit and open circuit failure, to ensure continued power supply to maintain the lighting and the transmission signal, there is enough to protect persons safe evacuation of the time, and is conducive to fire-fighting and reduce losses.

XLPE insulation LSOH cable is particularly suitable for the underground railway, underground shopping malls, shopping malls, buildings and other densely populated, ventilation constrained occasions.

3、Technique features

This product is manufactured by SV method, the straight-chain polyethylene will be changed as network structure by use this method, which transformed thermoplastic material into thermosetting material. The working temperature is up to 90℃, which can raise the cable current capacity highly.

The product has good performance on electrical characteristic, heat resistance, chemical resistance, environmental stress cracking resistance and aging resistance, all which make the cable has a long useful life.

The product characteristic is simple structure, short production period, easy installation and maintained, especially there is no limit of head drop during the cable laying.

4、 Operating characteristics

1. Rated power-frequency voltage U0/U:3.6/6kV~26/35kV.

2. Max. admissible operating temperature of the conductor:90℃.

3. Max. short-circuit temperature of conductor shall not exceed 250℃.(5s maximum duration)

4. During the cable laying, the ambient temperature must be above 0℃.

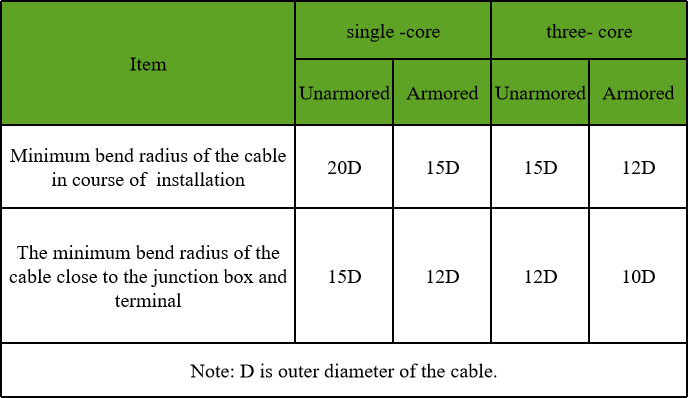

5. The bend radius:

The bending radius of a single-core cable should not less than 20 times of the cable diameter.

The bending radius of a single-core cable should not less than 15 times of the cable diameter.

The minimum bending diameter must be above the following standard:

6. Laying method:

There is no limit of head drop during the cable laying.

The cable may be laid in indoor, outdoor, air and soil. The cable may be immersed in water locally.

The cable may be laid in tunnel, pipe, trench, conduit and on cable bridge. The armored cable can be laid underground, and the wire-armored cable can be laid vertically.

The single core cable mustn't be laid in the magnetic metal pipes.

The environment of cable laying shall be in good heat dissipation condition.

7. The maximum allowed haul-off force and lateral pressure of cable.

The calculating method of the maximum allowed haul-off force:

——Copper conductor:F=70×S(N/mm2).

——Aluminum conductor:F=40×S(N/mm2).

The calculating method of the maximum allowed lateral pressure.

P=F÷R(N/m)The maximum allowed lateral pressure ≤3000N/m..

In the formula:

F-lateral pressure,N;

S-conductor section,mm2;

P-lateral pressure,N/m;

R-Cable bending radius,m.

8. The requirements on transportation and storage.

The cable reels shall not be delivered and stored in flat state

It is strictly forbidden to push the cable reel from the high level in order to prevent the cable from damages.

If the cable should be used section ally, the head of the cable must be sealed in order to prevent water intake.

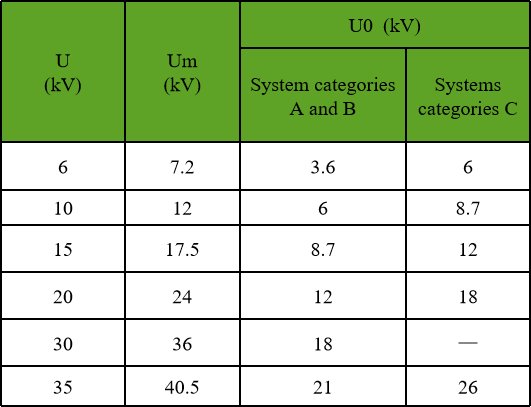

5、Voltage designation

The rated voltage of the cable for a given application shall be suitable for the operating conditions in the system in which the cable is used, and is expressed in the form of U0/U(Um)kV . Where:

U0-The rated power-frequency voltage between conductors and earth metallic screen, for which the cable designed;

U - The rated power-frequency voltage between conductors, for which the cable designed;

Um- The maximum value of the “highest system voltage” for which the equipment may be operated.

Rated voltage of cable to be used in three-phase systems are listed below:

System category A──This category comprises those systems in which any phase conductor that comes in contact with earth or an earth conductor. is disconnected from the system within 1 min.

System category B ──This category comprises those system which under fault conditions, are operated are operated for a short time with one phase earthed. This period should not exceed 1h. For a longer period, not exceeding 8h on any occasion can be tolerated. The total duration of earth faults in any year should not exceed 125h.

System category C──This category comprises all systems which do not fall into A and B.

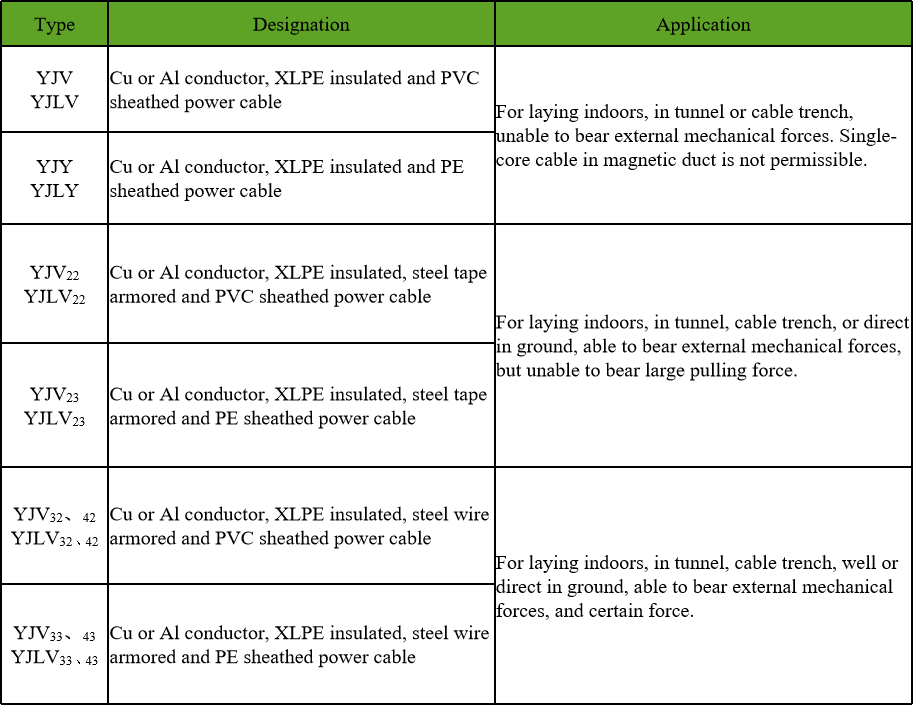

6、Type of cable

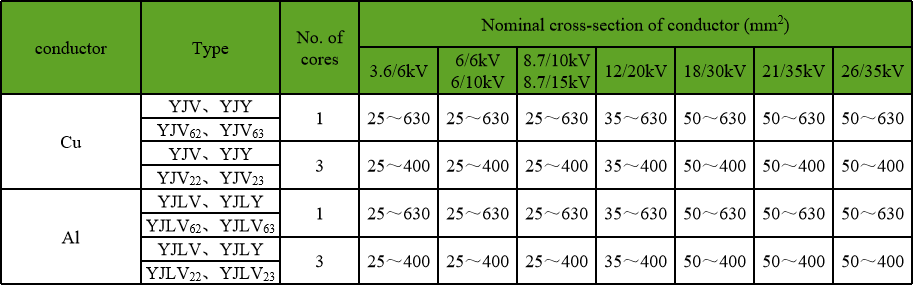

7、Production range of cable

Note:The armored single-core cables are used for D.C. system only, as for A.C. system, the magnetic isolation should be applied on the non-magnetically armored layer or non-magnetically material should be used.